It would not be an exaggeration to say that we are fast progressing into the new era of big change—one after another—in the environment, technology, society and thereby in the market. This requires all to rethink about the sustainability but also introduces us to the concept of circular economy to which current businesses start to align the company’s values accordingly. In striving for business growth, UBE will utilize its strength in innovation to enable a greater creative ability for all. Under such circumstances, UBE Group (Thailand) is set to take this as our challenge as opportunity to create new values for the benefits of our customers while continuing to make sustainable business growth.

UBE Global Innovation Center is our main R&D hub for undergoing our research and development activities. Located in the IRPC industrial estate, Rayong and in proximity of our production base, the center also features an adjoining exhibition space to disseminate information about UBE’s technology.

UBE Technical Center (Asia) Limited, or UTCA was founded in 2004 with determination and commitment to fulfill the research and development functions as well as to offer advanced analysis services to global UBE Group and our customers. Every step forward is our way to uphold and realize the vision of UBE Group (Thailand), “success driver through innovative technology and operational excellence.”

Located in UBE Global Innovation Center, UTCA is one of the region’s most advanced laboratories equipped with state-of-the-art facilities and equipment.

The core research fields in UTCA encompass different areas of Chemistry, specific realms of polymer synthesis compounding and process engineering. These areas of R&D correspond to the UBE Group’s business domains and beyond to keep ahead of the trends. In order to accelerate the research and development, UTCA fosters a myriad of collaborations with leading Thai universities and various institutes. Furthermore, UTCA is aiming to facilitate open innovation for the future in corporation with other companies. Keen to develop excellent human resources, we continue to go to a great length at investing in the human capital.

Polyurethane (PU) is one of the most versatile materials in the world, finding applications in almost all modern industries.

The properties of PU could be customize by using various types of oligopolyol and diisocyanate compound, to serve the broad spectrum of applications involved coating, adhesives, sealants, foams and elastomer. The aliphatic polycarbonate-diol (PCD) is one of the oligopolyol, providing the specialty type linear PU which has superior properties in terms of high chemical resistance, high hydrolysis resistance, high heat resistance, high abrasion resistance and high mechanical strength when compared to polyester and polyether-based PU.

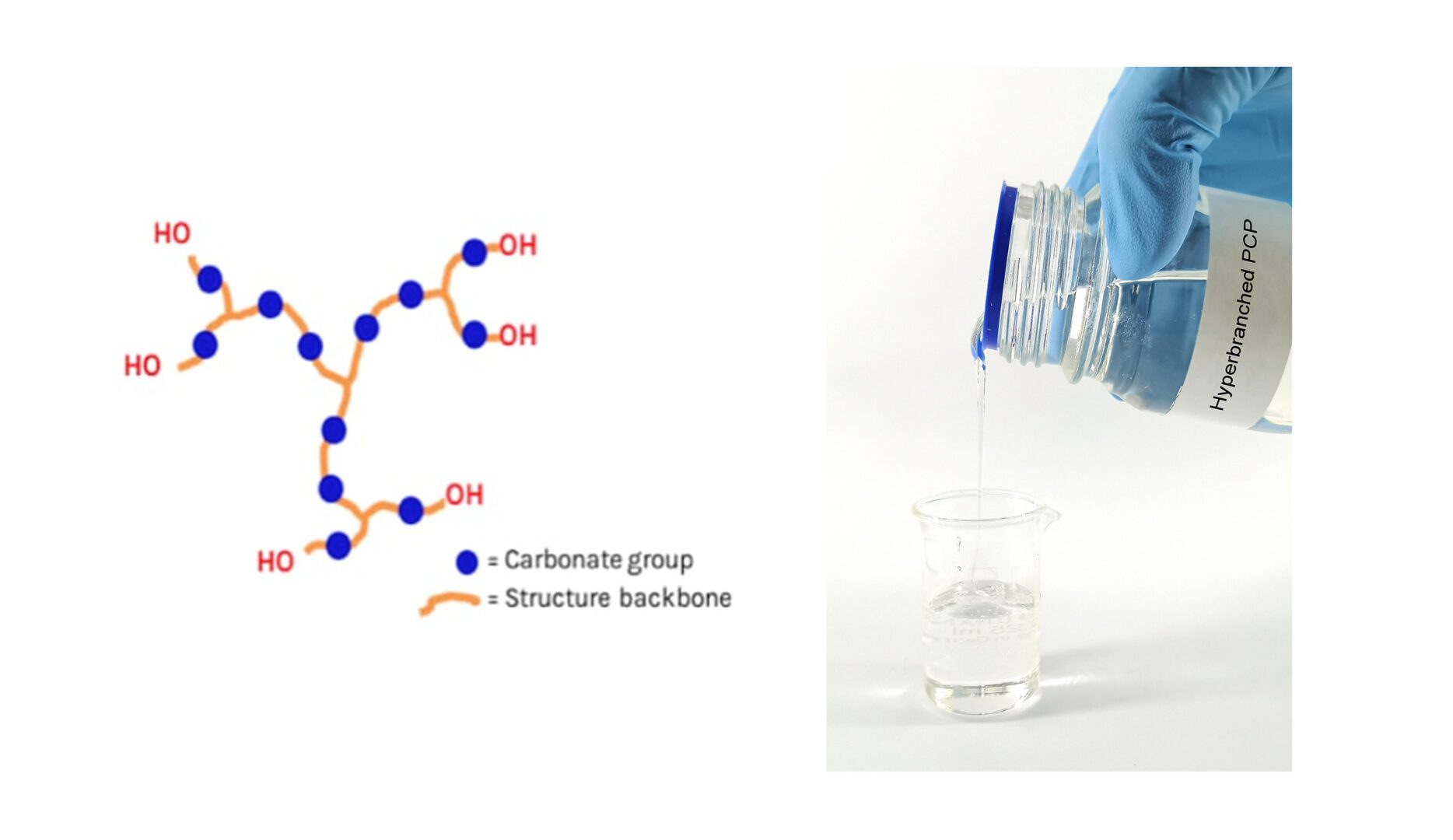

However, the application of linear molecular structure was limited by high strength coating application. Thus, the aliphatic hyperbranched structure would be developed for enhance the properties of linear oligopolyol based PU.

Originate by our development team through collaboration with Chulalongkorn University, the Hyperbranched polycarbonate polyol have been intensively investigated as the novel materials.

The branched aliphatic structure in polycarbonate polyols possesses high functionality of hydroxyl group, solvent free, low viscosity and is designed to for a wide range of polyurethane formulations.

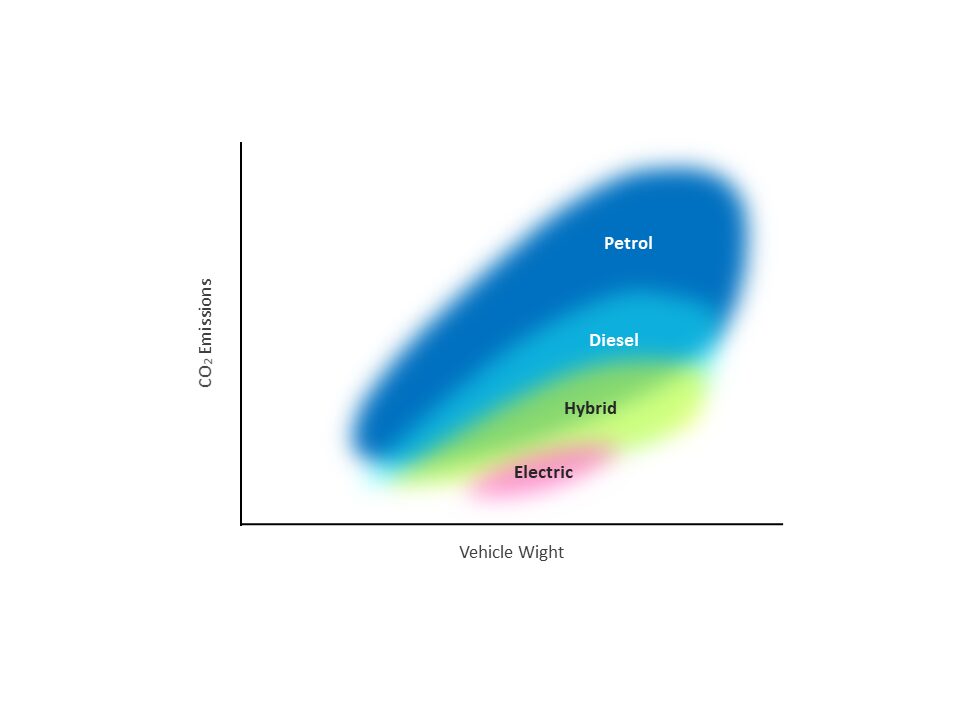

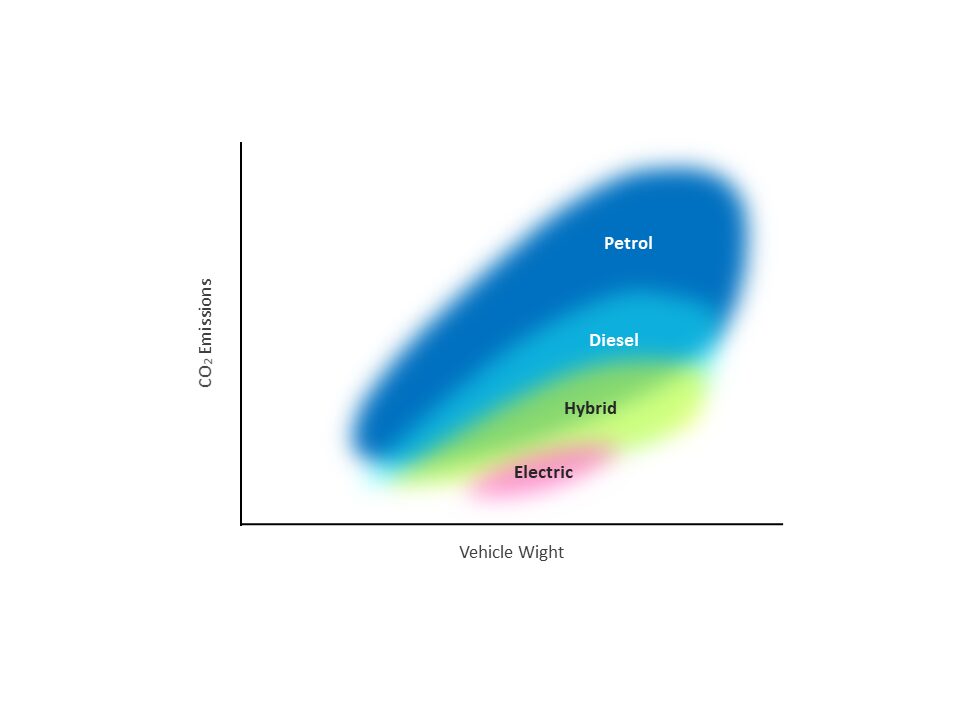

The technology of engineering plastics for automobiles is progressing rapidly. Thanks to its excellent thermal resistance and impact property, nylon has become one of the most widely used engineering plastics. We are developing our technology for nylon to meet market demands for further improvement of fuel efficiency and durability of automobiles. UTCA keep challenging to enhance the functionality of our nylon by making full use of our composite technology.

In recent years, the demand for eco cars; such as FCVs and EVs is on the rise. This results in a shift in the requirements for material properties that differ from those used for gasoline-power vehicles. We are constantly challenging ourselves and pushing boundaries in the area of new composite technology.

The human being is currently living paradoxical and challenging situations.

The world population is growing fast and will reach 9,7 billion people by 2050. The needs for food will increase at the same rate.

However, today, 1,3 billion tons of food (30% of the world production) is wasted every year while millions of human are suffering from food insecurity.

Besides the food waste is responsible of large CO2 emissions and consume unnecessarily precious resources such as water.

For years, packaging appears as a solution to extend the shelf life of the food and contribute to reduce the food waste.

Plastic became the reference material for the food packaging. It is light, resistant, hygienic, widely available and cheap.

However the over consumption, the improper packaging design and the mismanagement of the plastic waste create new challenges

UBE is convinced about the benefits of performance packaging to save food and at the same time is aware of and want to solve the current environmental plastic waste problems.

UBE’s R&D Team is permanently developing, in collaboration with all the value chain, new UBE NYLON grades and new film structures to improve the performances of the films while downgauging the packaging (saving food and plastics and the same time)

UBE’s R&D Team is also currently intensively working to demonstrate that after a first use in a performance packaging, UBE NYLON can be recycled and be reused again and again.

For more information, please visit our Change & Challenge platform

Giving rise to sustainability by use of bio materials replacing fossil resources is required by today’s global society.|

UTCA was first to exploit possibility in use of natural oil, which is abundant in South East Asia, for synthetic rubber.

Oil-extension (incorporation of oil into rubber) is utilized to improve physical properties of rubber, and petroleum based oil has been used conventionally.

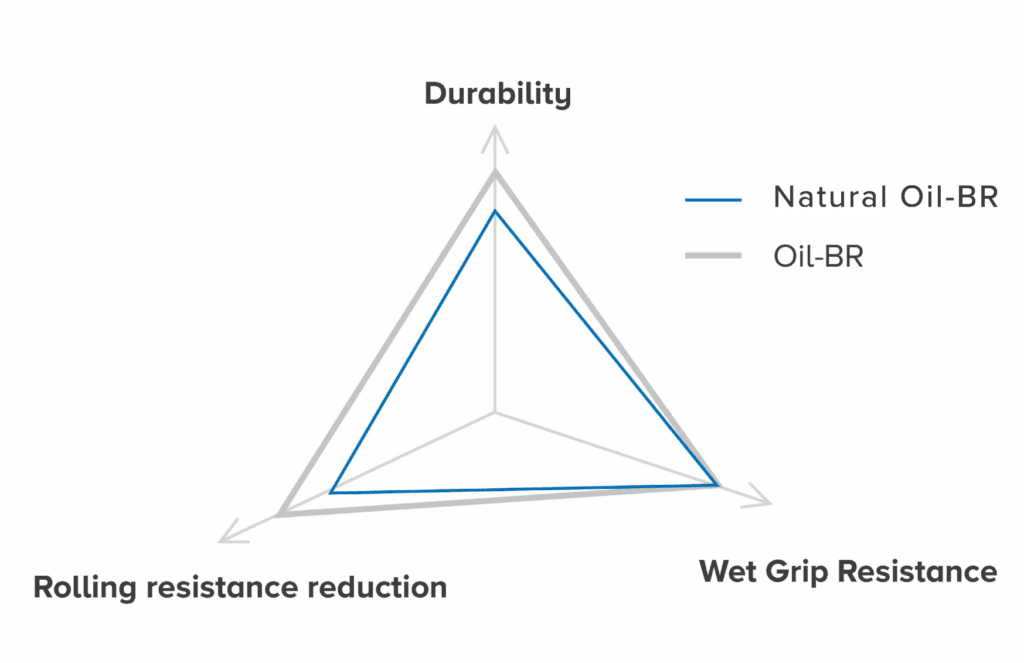

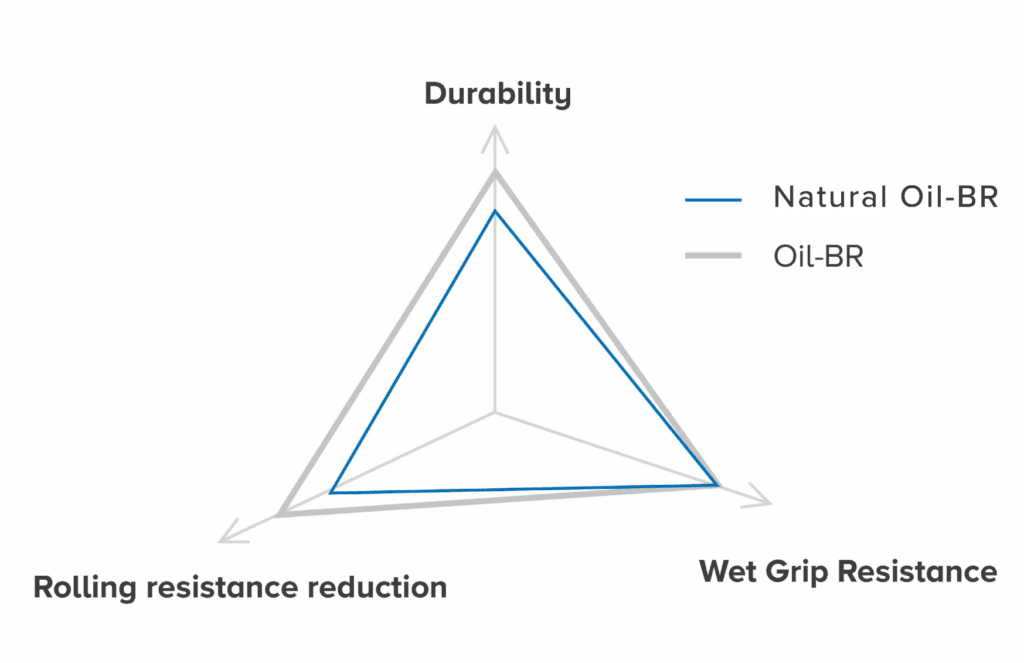

Our new concept is use of natural oil to enhance tire performance, as like abrasion resistance, rolling resistance and wet grip property of tire whereas keeping good processability.

UBEPOL BR®, Synthetic Rubber Natural Oil

The developed sample shows excellent performance as shown below.

![]()

![]()

![]()

![]()

![]()

![]()